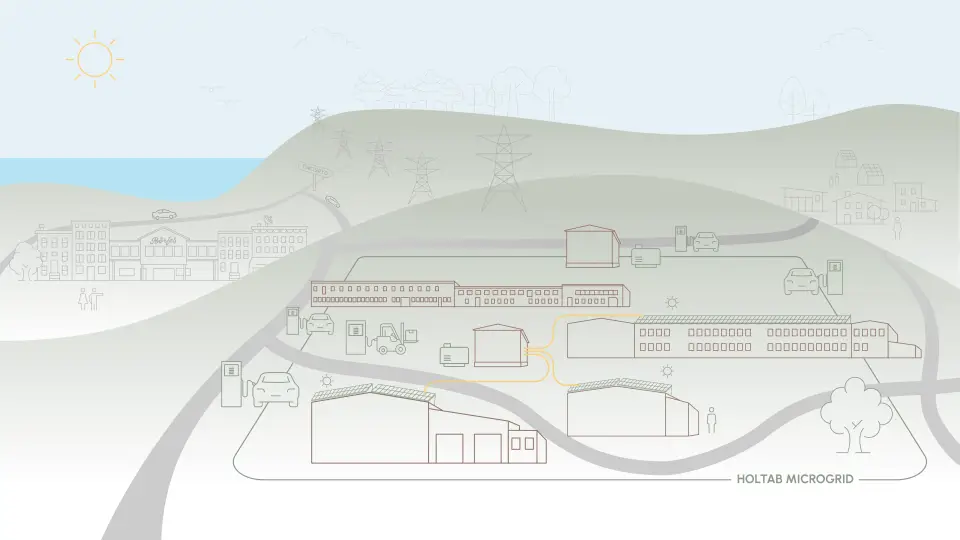

Holtab strengthens preparedness in Tingsryd – ready for island operation with its own microgrid

Holtab in Tingsryd has taken an important step to strengthen both its own operations and local energy preparedness. The company has built a microgrid – a local power system with integrated backup generation – enabling the factory to operate in island mode and maintain production even if the main power grid goes down.

“We are one of the larger employers in the region and supply products to critical parts of society. That makes it essential for us to keep operations running even during disruptions to the power supply. This is a long-term investment that strengthens both our business and the surrounding community. Reliable energy supply is a key part of our overall continuity work,” says Michael Fohlin, CEO of Holtab.

How the system is designed

Island operation means that the facility can disconnect from the main grid and continue operating independently. At Holtab, the solution includes backup power generation, intelligent switching and systems for monitoring and controlling electricity consumption.

This enables the business to secure its own power supply during disruptions while also helping to reduce strain on the public grid during outages. The backup power solution has been fully tested under operating conditions and is now an integrated part of Holtab’s microgrid.

The installation also includes local power generation from solar panels, charging infrastructure and several interconnected substations. In parallel with the technical solution, Holtab has worked systematically with crisis preparedness, analysing different scenarios and reviewing procedures for operations and IT security.

Sharing experience

Holtab sees strong value in sharing the experience gained from the project and will continue to communicate insights and lessons learned.

“Society is increasingly dependent on electricity and therefore more vulnerable to disruptions. When more organisations are prepared, local stability improves, benefiting both business and society. Our starting point has been to build robustness and secure Holtab’s continuity, and we are happy to share those experiences,” says Michael Fohlin.

Learn more about the technical solution.

About Holtab

Holtab is one of the Nordic region’s leading suppliers of secondary substations, primary substations, prefabricated power solutions, technical buildings and low-voltage switchboard. The offering also includes service and digitalisation services. The company was founded in 1973 and is family-owned. The head office and main factory are located in Tingsryd, Sweden, with additional production in Lidhult and Olofström, as well as operations in Denmark, Finland and Norway.

The company reported net sales of approximately 1,290 MSEK in 2024. Around 330 employees deliver roughly 2,000 products annually to customers in the energy, industrial and infrastructure sectors.

Frequently Asked Questions

Modern society is more dependent on electricity than ever before, and at the same time more vulnerable to disruptions. For Holtab, this investment is about taking responsibility by securing our own operations over the long term and contributing to Sweden’s total defence resilience in a world where power outages can occur for many different reasons.

It is also about ensuring reliable deliveries to our customers, many of whom operate within critical infrastructure and essential services.

In theory, yes. However, our microgrid is currently designed and dimensioned to support Holtab’s own operations. At the same time, it demonstrates how local energy systems can reduce both dependency on and strain on the public grid during outages.

In the longer term, experience from solutions like this may create opportunities for collaboration, but there are no such plans or decisions in place today.

No. There is currently no legal requirement for Holtab to build a microgrid. This is a voluntary initiative to strengthen operational reliability and improve preparedness for potential power outages or crisis situations.

For some organisations, the situation is different. Operators within critical sectors such as energy, healthcare, social care, food supply and critical industry are already subject to requirements for continuity planning and preparedness. These requirements are gradually being strengthened, including through EU legislation such as the CER Directive.

“We supply many organisations that carry significant responsibility for keeping society functioning during crises and periods of heightened preparedness. That is why we believe it is important to take responsibility ourselves, stay ahead and share our experience with others facing similar challenges,” says Michael Fohlin, CEO of Holtab.

The starting point in our continuity planning is that we should never end up without power. The system is therefore dimensioned to run Holtab’s site in Tingsryd for extended periods. Endurance is mainly determined by electricity demand, solar generation and access to fuel for backup power.

We have worked with these routines for a long time and collaborate with external partners, for example to secure fuel supply.

No. This is a fully operational solution used in our day-to-day operations. The microgrid has been tested in real operation by simulating a complete loss of grid power, including start-up from a fully de-energised state, to ensure that both start-up and ongoing operation work as intended.

No. Backup power is one component, but a microgrid also includes switching, control systems and a holistic approach to how power supply is managed during an outage. It is about controlled, long-term operation – not just starting a generator.

If the public grid fails, the facility is automatically disconnected and switches to island mode. Backup power takes over and operations continue according to predefined priorities.

The project has given us valuable hands-on experience, and we are happy to share our insights with others facing similar challenges related to operational reliability and preparedness.

Questions about microgrids and island operation: Mohamed Ezzo, Innovation Manager

Questions about continuity planning and organisational resilience: Michael Fohlin, CEO

Contact

Michael Fohlin

CEO