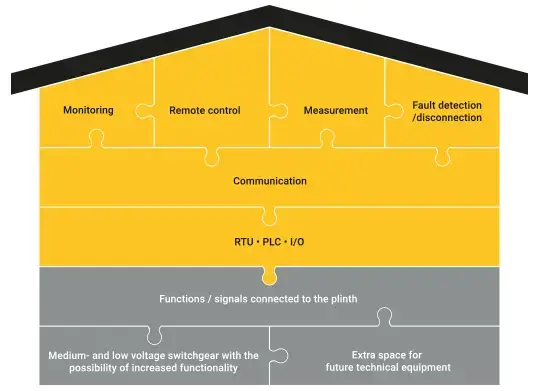

Complete solutions for substation automation

We offer complete solutions from leading suppliers of substation automation. This is because they are equipped with a central RTU/PLC unit and the required number of I/O units, indicators, remote communication equipment and power supply/UPS to meet your exact needs.

Everything is programmed and ready to use. This means a substation automation solution can be implemented at a low cost to assure communications between the station and a system such as SCADA.

These substation automation solutions extend from mounting plates for indoor use to weather-protected encapsulations. When a customer orders a turnkey solution, it is delivered fully assembled and tested as specified. Some solutions can be verified all the way to the customer’s SCADA from our factory if desired.

We work together with a range of suppliers such as Netcontrol, ABB, Schneider, Smart Network Networks and Techinova, etc.

System and monitoring

We offer a broad range of RTUs that monitor, control and communicate with the substation including status indication of primary equipment as well as current, voltage and energy metering on the low-voltage side. Monitoring and control of other parts such as the substation’s perimeter protection, alarms and ventilation is also possible, everything adapted to individual needs.

Uninterrupted power supply inclusive of battery handling (UPS)

A grid automation cabinet must continue to operate long enough to carry out a number of steps in the event of a power outage. The extra power needed to reconnect load or power switches requires a special high-performance local battery with an extensive temperature range. Depending on the make, the equipment is supplied with power via 12/24/48 VDC.

- Standby power units that normally supply 115 and 230 VAC

- UPS batteries adapted to the maximum required current, charging and standby times. Typical values are 6-8 hours charging time and 12-48 hours standby time in the event of a power outage.

- Monitoring of the UPS and battery for preventative maintenance

Fault detection and disconnection of faults We use various types of ground fault indicators and short-circuit detectors which communicate with the RTU to record a wide range of information. With the aid of indicators, data can be obtained on parameters such as current, voltage, power output (S, P, Q), power output factor, frequency, ground faults and short-circuits on the medium-voltage side. To assure the selective disconnection of faults, a solution with a protective relay together with switches in the substation should be chosen. Metering By means of internal communications between the RTU and the energy meters, parameters on the low-voltage side of the substation can be obtained.

- Metering of voltage and current

- Metering of power, S, P, Q cosφ

- Metering of electrical quality: THD, harmonics, etc.

- Metering of over and under-voltages.

Communications

Holtab offers a number of communications solutions via its suppliers. These include communications via the Net 1 public networks and mobile networks (2G, 3G, 4G), but we can also offer communications with special security solutions for isolated communications networks that satisfy the high requirements of state-of-the art applications, via copper wiring, optical fibre or wireless mode. Communications to SCADA take place either via standard protocols or as encrypted transmissions.