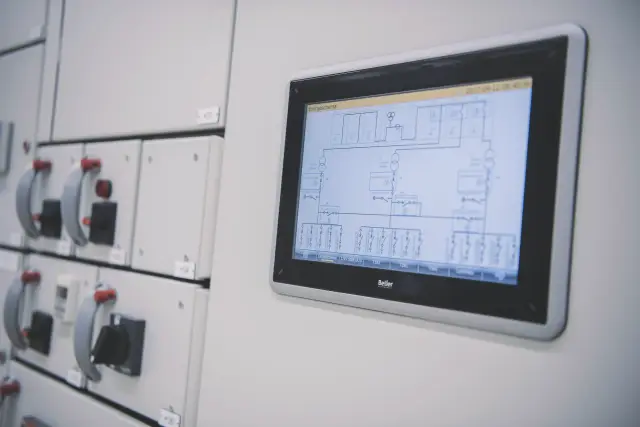

The more unique requirements – the better the delivery of Holtab

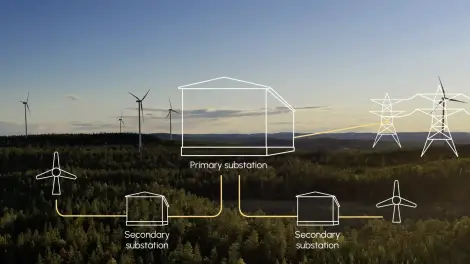

With over 50 years of experience in delivering power solutions, Holtab has gained a prominent role in the industry. Not least when it comes to tailor-made products and solutions. “Working customer-specifically requires a high level of commitment and knowledge,” says Ola Hedqvist, Sales Engineer.